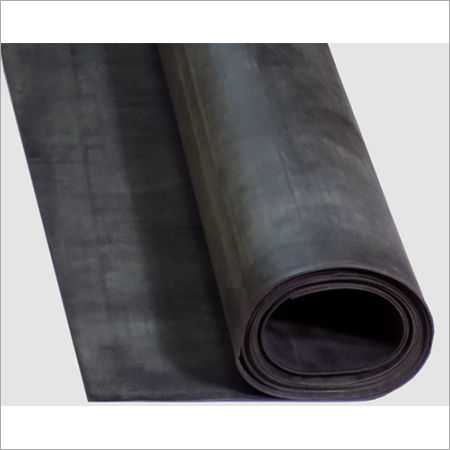

EPDM Membrane

Price 180 INR/ Kilograms

EPDM Membrane Specification

- Product Type

- EPDM Membrane

- Hardness

- 66+-5 Shore A

- Thickness

- 1mm to 25mm thk Millimeter (mm)

- Tensile Strength

- 12 Mpa Megapascals (MPa )

- Color

- Black

- Length

- 1200mm x 10 mtr long Millimeter (mm)

EPDM Membrane Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 7 Days

About EPDM Membrane

EPDM Membrane is a rubber-based waterproofing membrane that is exceptionally durable. By embossing the membrane, it provides a textured surface that improves adhesiveness when using cold adhesives and heat sealing. Its utilized to create airtight and watertight seals at interfaces. This is mostly resistant to water, ozone, UV, and weathering. EPDM Membrane is crucial for any structure since it never allows water to pass through and keeps its excellent quality over time. It can tolerate structural movement, inclement weather, chemical degradation, and mechanical stress and strain.

Product Specification

|

Size |

1000 mm to 1500 mm wide |

|

Temperature |

(-45 degree C to 150 degree C) |

|

Thickness |

1mm to 5mm |

|

Material |

EPDM |

Exceptional Weather and Ozone Resistance

EPDM membranes are engineered to withstand harsh weather, UV radiation, and ozone exposure. This makes them an ideal choice for both indoor and outdoor applications where long-term durability is essential. Their chemical formulation ensures they retain flexibility and mechanical properties even under extreme environmental conditions.

Customizable Thickness for Versatile Use

Available in thicknesses ranging from 1mm to 25mm, this membrane can be tailored to suit diverse project needswhether for delicate waterproofing or heavy-duty industrial sealing. This adaptability ensures a perfect fit for various applications across construction, roofing, and insulation industries.

FAQs of EPDM Membrane:

Q: How is the EPDM membrane typically installed?

A: The EPDM membrane is typically installed by adhering, mechanically fastening, or ballasting it onto surfaces. The method depends on the application area, surface material, and thickness required. Professional installation ensures optimal performance and airtight seals.Q: What are the main applications of this EPDM membrane?

A: This EPDM membrane is commonly used for roofing, waterproofing, pond and tank lining, vibration dampening, and general industrial sealing. Its strong tensile strength and broad thickness options allow it to meet a wide variety of structural and protective needs.Q: When should I choose a specific membrane thickness?

A: Thinner membranes (1mm3mm) are ideal for lightweight waterproofing or lining, while thicker membranes (up to 25mm) are selected for heavy-duty sealing, impact resistance, or vibration isolation. The thickness used depends on the mechanical stress and environmental exposure involved in your application.Q: Where is this product manufactured and exported from?

A: This EPDM membrane is manufactured, supplied, and exported from India, ensuring competitive pricing and reliable international shipment. The production facilities are equipped to provide high-quality products for global supply chains.Q: What is the manufacturing process of EPDM membranes?

A: EPDM membranes are produced by compounding ethylene propylene diene monomer rubber with specific additives, rolling it into sheets, and curing it to achieve the desired hardness and tensile strength. Quality control ensures each batch meets industrial requirements.Q: What are the primary benefits of using this EPDM membrane?

A: The key benefits include superior resistance to weather, UV, and ozone, excellent flexibility across a wide temperature range, strong tensile strength for structural applications, and low maintenance costsmaking it a cost-effective, long-lasting solution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EPDM Membrane Sheet Category

EPDM Rubber Roll

Price 300 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Black,green,red

Product Type : EPDM Rubber Roll

Hardness : 45 to 80 shore A

Thickness : 1.0mm to 100mm Millimeter (mm)

EPDM Membrane Sheet

Price 10500.00 INR / Square Foot

Minimum Order Quantity : 1 Foot

Color : Black

Product Type : EPDM Membrane Sheet

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese