Rubber Checkered Sheet

Price 140 INR/ Kilograms

Rubber Checkered Sheet Specification

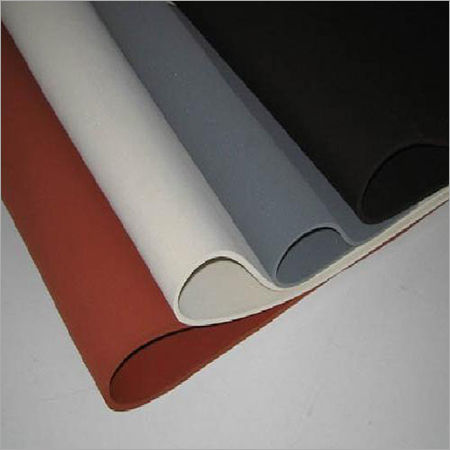

- Color

- Black

- Product Type

- Rubber Checkered Sheet

- Thickness

- 3mm,4mm,5mm,6mm Millimeter (mm)

Rubber Checkered Sheet Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

About Rubber Checkered Sheet

Rubber Checkered Sheet is utilized in a variety of industries since it is resistant to chemicals, pressure changes, and impacts. The flooring with a continuous checkered field pattern is made for high grip and is simple to clean. Indoor and outdoor uses for non-staining, non-discoloring mats. Apart from this, Rubber Checkered Sheet is completely weatherproof and may be used both inside and outside. High-quality rubber compounds are used to create checkered pattern flooring, which has remarkable wear and grip properties as well as surefootedness. This sheet is very effective as well as economical to use.

Product Specification

| Width | 1m,1.2m,1.5m |

| Colour | Black |

| Material | NBR,EPDM rubber sheet |

| Thickness(mm) | 3mm,4mm,5mm,6mm |

Versatile Flooring Solution

The Rubber Checkered Sheet boasts a unique checkered design that not only contributes to a professional appearance but also delivers exceptional slip resistance. Its robust construction and varying thickness options allow for adaptability across multiple settings, such as manufacturing plants, gyms, transportation, and more.

Quality Manufacturing in India

Our sheets are engineered in India, adhering to rigorous quality control standards. By utilizing premium-grade rubber, we guarantee consistency, durability, and long service life. As both a manufacturer and supplier, we offer tailored solutions to meet client specifications and industry requirements.

FAQs of Rubber Checkered Sheet:

Q: How is the rubber checkered sheet installed?

A: The rubber checkered sheet can be laid directly onto flat surfaces with or without adhesive. For enhanced durability in high-traffic areas, it is recommended to use a suitable adhesive to firmly secure the sheet and ensure long-lasting performance.Q: What are the typical uses of black rubber checkered sheets?

A: These sheets are commonly used for antiskid flooring in industrial units, vehicle decks, staircases, gyms, and workspaces. The checkered texture provides slip resistance, making it ideal for zones where safety is a priority.Q: When should a thicker sheet (4mm, 5mm, or 6mm) be chosen over a 3mm sheet?

A: Thicker sheets are recommended for settings with heavier loads, frequent movement, or increased impact risk. For example, workshops, ramps, and loading bays often benefit from 5mm or 6mm thick sheets, while lighter-use areas can utilize 3mm or 4mm options.Q: Where can your rubber checkered sheets be supplied or exported from India?

A: We supply and export our rubber checkered sheets globally, catering to clients across Asia, Europe, Africa, and the Americas. Our efficient logistics ensure timely delivery to your preferred location.Q: What is the manufacturing process of these rubber checkered sheets?

A: We use high-quality rubber compounds and mold them under heat and pressure to create sheets with a checkered finish. This process ensures consistency in thickness, texture, and overall quality.Q: How does the checkered surface benefit the user?

A: The checkered pattern enhances grip and significantly reduces the risk of slips, contributing to a safer environment. This design is especially valuable in areas exposed to moisture or frequent foot traffic.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Sheets Category

Food Grade Rubber Sheet

Price 225 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : White

Product Type : Food Grade Rubber Sheet

Length : From 10 Mtrs Rolls up to 25 Mtrs rolls. Meter (m)

NBR Rubber Sheet

Price 300 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Multicolor

Product Type : NBR Rubber Sheet

Tensile Strength : 10Mpa Megapascals (MPa )

Butyl Rubber Sheets

Price 325 INR / Kilograms

Minimum Order Quantity : 400 Kilograms

Color : Black

Product Type : Butyl Rubber Sheets

Length : 10150m Millimeter (mm)

Hypalon Rubber Sheet

Price 600 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Multicolor

Product Type : Hypalon Rubber Sheet

Tensile Strength : 7.0MPa Megapascals (MPa )

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese